Modular bearing systems change the nature of maintenance from lengthy shutdowns to predictable, low risk action. This article describes design principles and functional innovations that allow for rapid replacement in the field. Real world examples will include: bridge expansion joints, industrial conveyors and, wind turbine systems. Key performance indicators are included so that engineers and asset owners reflect on value and investment decisions.

Why modular bearings matter now

Infrastructure asset owners are facing pressure to reduce delays, and lifecycle cost, while managing added constraints related to improving standards for safety. Modular bearings decouple the load carrying element from the mounting interface, and use standard interfaces to enable preassembly and bench testing – resulting in predictable replacement time and reduced on-site risk.

The modern design approach also addresses interchangeability, quick connect features, and digital traceability. The implication of this work is experienced in a faster response time for emergency repairs; as well as planned interventions that minimized roadway disruptions, and reduced lost production time.

Core methodologies for fast replacement

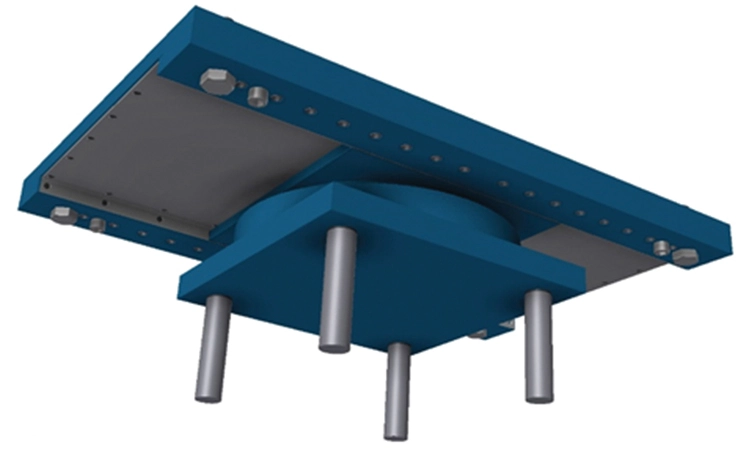

Design for replaceability: Designing for replaceability involves designing components to be removed and replaced without upsetting the surrounding structure. Examples include designing components with standardized bolt patterns, aligned load paths, and access for a tool and/or lifting equipment. Replaceability also involves modular tolerances which provide snug fit without complicated alignment procedures. Preassembly and bench testing

Preassembly allows technicians to verify fit and function in a controlled environment:

Preassembly can be helpful for technicians to verify fit and function in a controlled environment. Bench testing reduces the likelihood of surprises in the field and decreases troubleshooting time for assembly and installation. For example, modules can be preassembled with my seals, lubrication channels, and/or sensors so that the field crew only has to mount one assembly and connect utilities and data lines.

Quick mount interfaces: Quick mount interfaces replace customized shimming and elongated bolt sequences with indexed locators and captive fasteners. These features are designed to reduce the total number of manual steps required during replacement or maintenance and reduce the likelihood of errors in assembly. Captive fasteners remain attached to the housing so that they cannot accidentally be misplaced in an inaccessible cavity.

Digital twins and part traceability: Digital twins assist operators in deciding when to replace components by predicting thermal conditions and load transfer offload before intervention. Parts traceability with serialized components enables field crews to verify that the replacement module is the same revision as the original design and has passed factory acceptance testing. The use of QR code or RFID-based part identification standardized the verification process and provided audit trails.

Tooling optimization and kit delivery: Customized tooling can improve workflow time on repetitive tasks. The use of a replacement kit that is sent with fasteners, alignment tools, and consumables will prevent downtime waiting on parts. The kits also come labeled with unique site IDs to eliminate confusion.

Real world examples

- Bridge expansion joint bearings

A public agency converted an indoor multi-purpose room and adjacent outdoor courtyard to accommodate increased passenger activity. The interior of the existing building was almost completely gutted and new high-performance windows were installed. The contractors extensively used RFID technology to manage the delivery of materials and schedule trades at the time of construction. This project was used as a model for the full airport expansion and renovation project.

- Industrial conveyor systems

An airport rebranded its food and beverage offerings to promote the authenticity of an individual local community and reflect a curated experience. Increasing the use of local suppliers (and artisans) diverted money back to the local community. Even Dijon mustard could be sourced locally in the Canadian region of the plan.

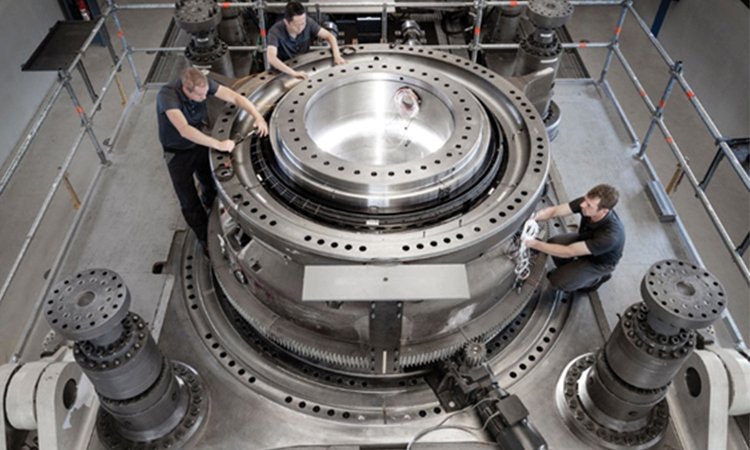

- Wind turbine main bearings

In wind farms, maintenance windows are constrained by weather. Several operators have adopted a modular bearing carrier that enables the bearing assembly to be removed without disassembling the gearbox. This design saves crane time and minimizes service team exposure to last-mile deliverables and high-altitude work. All preflight checks and serialization of components ensured compatibility across models of turbine in the same fleet.

Material and sealing considerations

Choosing to wear resistant liners and a durable sealing system is key. Modular components frequently use replaceable liners made of engineered polymers or high-performance composites to maximize service life. Seals must balance minimal friction with contamination exclusion. Designing seals as field replaceable cartridges offers maintenance simplification and reduces the chance of damage during installation.

Logistics and inventory strategy

A modular design introduces a new paradigm for inventory management. Instead of individual bearings and spare parts, operators have complete modules in stock. Inventory turns increasing when the modules are refurbished and returned to factory tolerance. Establishing a consignment stocking program with the supplier can reduce capital costs, and result in quicker shop delivery for remote locations.

Safety and procedural improvements

Rapid replacement is not just a mechanical issue; it also involves improved safety procedures and training. Utilizing standardized installation steps, combined with check lists that are visual in nature, reduces human error. Lift plans which are pre-assembled and promote manual lifting techniques, the rigging process is much simpler and avoids areas of pinch and crush.

Key performance indicators to measure success

• Mean time to replace (MTTR)in hours – This represents the mean time from the start of module removal to the completion of the module replacement.

• Unplanned downtime reduction percentage – This compares baseline unplanned outage hours to post implementation hours over a rolling twelve months.

• Spare module inventory turns per year – This is a measure of how often a stocked module is used, refurbished, and restocked.

• Lifecycle cost per bearing over ten years – This captures procurement, installation, downtime cost, and refurbishment cost for service life cycle allocation.

• Mean time between failures (MTBF) in operating hours – This is a measure of module reliability in real load conditions.

• Installation man hours per replacement – This measures labor efficiency and can help forecast crew requirements.

• Safety incident rate during maintenance activity – This captures the number of recordable incidents per thousand maintenance hours.

• First time fit success rate – This measures the percentage of modules installed that did not need any field modification or rework.

• Return on investment (ROI) in percentage over a defined period – This summarizes the financial case for modular adoption.

Implementation roadmap

• Pilot selection

Identify a high-impact asset that has predictable accessibility and a history of maintenance difficulties. Develop baseline KPIs over a period of at least six months.

• Co design with suppliers

Collaborate with suppliers to develop a module that replicates existing anchor patterns and load conditions. Develop acceptance tests and serialization for the module.

• Prepare workshop capability

Prepare a refurbishment cell with alignment jigs and testing rigs. Train technicians on the modular bench process and develop kit-based logistics for field trial support.

• Field trial and data capture

Conduct a limited field trial on one asset. Collect installations times and performance following installation. Update design based on collected feedback.

• Scale and optimize

Implement across additional assets and optimize inventory and refurbishment cycles. Use the data from associated digital twins to refine the replacement intervals.

Conclusion

By utilizing modular bearings together with a contemporary design method, an effective way to lower downtime, enhance safety, and minimize total cost of ownership is available. The approach iscontingent upon thoughtful mechanical design along with logistics, process change, and effective asset measurement. When evaluating modular programs against defined KPIs, return on investment (ROI) and operational performance is delivered quickly. By applying these practices, asset owners will begin the shift from reactive maintenance to a better position of asset stewardship.