Precision bearings form the heart of rotating systems where accuracy, stability, and performance at high speeds are non-negotiable. In large-diameter applications—ranging from wind turbine main shafts to aerospace test rigs, large machine tools, medical imaging equipment, and high-speed turbines—bearing design becomes an engineering challenge that demands innovation.

As rotational diameters increase, loads multiply, centrifugal forces intensify, thermal effects rise, and achieving micrometre-level precision grows more difficult. Large-size bearings must therefore deliver exceptional rigidity, speed capability, dynamic stability, and long service life while minimizing friction losses.

Advanced materials, complex geometries, and precision manufacturing technologies are making this possible.

Balancing Size and Speed: The Core Design Challenge

Scaling up bearing diameter is not simply about increasing physical dimensions; it changes the entire load distribution and dynamic behavior. High-speed rotation subjects rolling elements to huge centrifugal loads, leading to contact stress changes, raceway deformation, and lubrication film instability.

Moreover, the larger the diameter, the higher the potential for imbalance or vibration forces. Optimized internal geometry, reduced friction components, and lightweight materials become critical to strike the right balance between speed and load needs.

Optimized Internal Geometry for Load and Rigidity

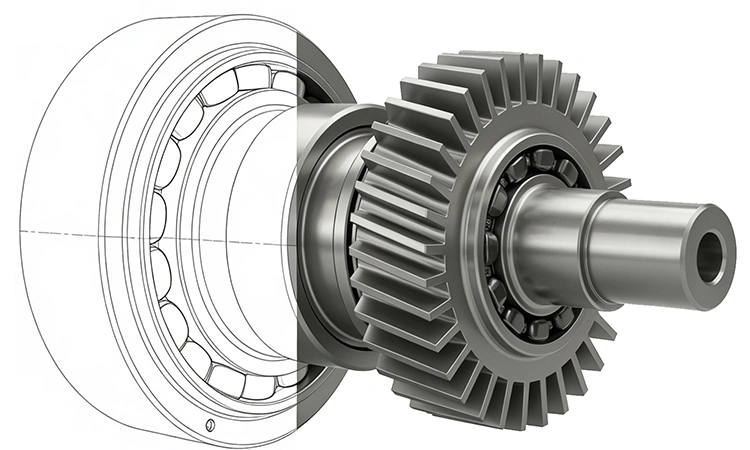

Precision large-diameter bearings often rely on specialized profiles like logarithmic raceway curvature and advanced roller end designs to distribute loads more evenly. Cross-section optimization improves rigidity without adding unnecessary mass. For applications involving axial thrust and radial loads simultaneously—such as aerospace or large spindles—tapered or cylindrical roller bearings with enhanced contact angles maintain system alignment and rotational accuracy.

In machine tool spindles, where dynamic stiffness defines cutting performance, hybrid angular contact arrangements help minimize deflection and vibration for superior machining accuracy.

Hybrid Bearings for High-Speed Performance

Ceramic rolling elements have become a staple for high-speed precision bearings. Silicon nitride balls or rollers provide significant performance advantages: they are 60% lighter than steel, reduce centrifugal effects, minimize heat generation, and resist wear. Ceramic hybrids exhibit longer lubricant life due to smoother, harder surfaces that reduce micropitting and skidding.

In large bearing assemblies—such as energy sector spindles—hybrid solutions enable stable high-speed rotation with lower energy consumption.

Managing Thermal Expansion and Heat Generation

Heat management is a major challenge in large and high-speed bearings. Excess heat leads to changes in preload, lubricant failure, and reduced bearing life. To counter this, engineers deploy multiple techniques: cage materials with low thermal expansion, coatings that reduce boundary friction, and advanced preload adjustment mechanisms to maintain optimal internal clearance across varying temperature conditions.

In high-speed turbine applications, active cooling and optimized lubrication channels are engineered to extract heat precisely where it is generated.

Lubrication Engineering for High-Speed Operation

Ensuring consistent lubrication film integrity over large raceways is complex. High-speed applications demand oils with superior film strength and anti-foaming characteristics, while heavily-loaded systems may require advanced greases with additives for wear resistance.

Oil-air lubrication systems have become standard in high-precision spindles, balancing lubricant supply with minimal drag. Computational fluid dynamics (CFD) aids in optimizing lubrication channel geometry to ensure the right amount of lubricant reaches every contact zone, even under extreme speeds.

Material Advances Boosting Fatigue Life

High-grade steel remains the material of choice, but today’s bearings rely on extra-clean steels with refined microstructures that dramatically enhance fatigue strength.

Heat-treated variants—carburized or case-hardened—offer superior resistance to shock loads, minimizing subsurface crack initiation in demanding environments. For ultra-high-speed rotation, titanium cages, carbon fiber-reinforced retainers, and PVD-coated surfaces further elevate performance through weight reduction and enhanced wear resistance.

Preload Engineering for Vibration-Free Motion

Preload accuracy is vital in bearings that must operate at high speed with zero vibration and minimal runout. In wind turbine pitch bearings or radar antenna drives, any misalignment can induce chatter or fatigue damage.

Advanced preloading techniques—such as spring-loaded mechanisms and optimized bearing pair configurations—ensure consistent stiffness and rotational precision over long operating hours.

Digitalization and Smart Monitoring Enhance Reliability

With large precision bearings often installed in mission-critical assets, real-time condition monitoring is now standard. Embedded sensors track vibration signatures, temperature profiles, lubrication condition, and load patterns. Predictive analytics help identify early degradation, allowing planned interventions that prevent catastrophic failures.

Digital twins simulate operational stresses, enabling engineers to optimize bearing geometry for both current and future performance demands.

Future Outlook: Toward Superior Performance and Sustainability

Next-generation precision bearings for high-speed, large-diameter systems will continue to adopt lightweight structures, high-performance ceramics, and intelligent lubrication methods. Parametric design and automation in manufacturing will reduce tolerance variability, enhancing global consistency.

Sustainable lubrication systems and recyclable materials are growing priorities as industries push toward greener manufacturing.

The integration of sensing technology will further refine product reliability and uptime—making large-diameter precision bearings smarter, stronger, & faster than ever.