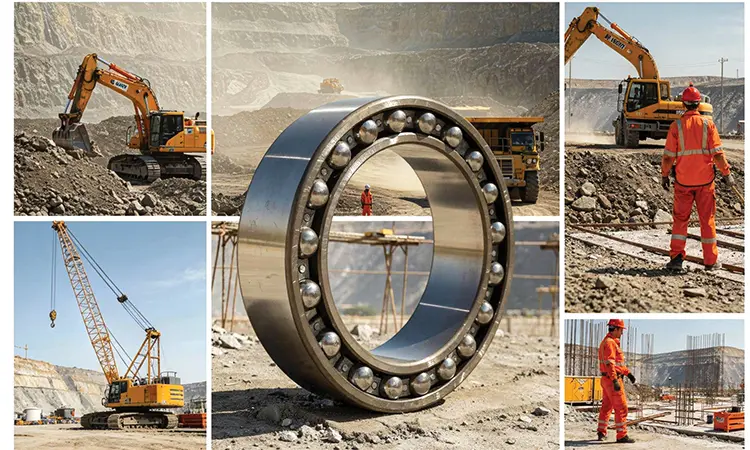

Mining and construction industries demand mechanical systems that deliver unrelenting performance under some of the harshest operating conditions on earth. Whether it is an excavator working in abrasive soil, a dump truck hauling ore up steep gradients, a crusher pulverizing rock, or a drilling rig boring through granite, every piece of equipment is subjected to extreme loads, constant vibration, dust contamination, moisture, and wide temperature swings.

Bearings—the overlooked yet critical components that enable rotation and articulation—must therefore be designed with extraordinary durability, resilience, and load management capabilities. Their reliability directly affects machine uptime, safety, operating efficiency, and lifecycle costs in industries where equipment failure can lead to costly downtime or hazardous situations.

Understanding the Operating Environment

Unlike controlled industrial facilities, mining and construction operations expose bearings to continual external aggressors. Dust, mud, sand, and water ingress are constant threats, leading to abrasive wear if not properly managed. Heavy shock loads from blasting, digging, or hauling place intense stress on rolling elements and raceways. Vibration transmitted from uneven terrain or rock fragmentation can induce premature fatigue.

Bearings must therefore be engineered not just for high dynamic load ratings, but also for contamination resistance and dimensional stability even under severe operating stress. The combination of heavy loads, slow speeds, shock, and contaminants makes these applications unique in bearing engineering.

Specialized Bearing Designs for Harsh Conditions

Heavy equipment such as wheel loaders, hydraulic excavators, dozers, and articulated dump trucks rely on spherical roller bearings, tapered roller bearings, and cylindrical roller bearings designed for high shock absorption and misalignment. Spherical roller bearings are widely used in conveyors, crushers, and vibrating screens due to their self-aligning properties and ability to withstand high radial loads.

Tapered roller bearings, with their inherently strong axial load capacity, are critical for wheel hubs, final drives, and gearboxes in mining trucks and earthmovers. Large slewing bearings, designed with hardened rings and robust cage arrangements, enable the rotational movement of cranes, excavators, and drilling rigs, maintaining stability even under uneven load distribution.

Contamination Control: The First Line of Defence

The presence of dust and fine particulate matter is perhaps the single greatest threat to bearing life in mining and construction fields. Contaminants act as abrasives inside the lubrication film, quickly escalating wear. Advanced sealing solutions such as labyrinth seals, heavy-duty lip seals, triple-lip designs, and metal-shielded seals are therefore essential. Many modern bearings incorporate integrated seal-and-shield systems that prevent ingress even during high-pressure washdowns.

In some applications, specially engineered “grease pockets” and flingers ensure that contaminants are expelled before reaching the critical contact zones. These integrated sealing systems significantly extend bearing life and reduce unscheduled maintenance.

Material Strength and Heat Treatment Innovations

Bearings for mining and construction equipment are typically manufactured using high-grade alloy steels with enhanced cleanliness and controlled microstructure. Carburizing and induction hardening techniques provide deeper case depths, improving resistance to shock and surface fatigue. Heat-treated rings with specially formulated carbon content help prevent cracking under impact loads.

In addition, rollers may feature surface finishing technologies such as superfinishing, graphite coating, or black oxidation to improve wear resistance and reduce friction under boundary lubrication conditions. These material enhancements are crucial in applications such as crushers or vibrating screens where loads fluctuate rapidly.

Lubrication Solutions Adapted to Extreme Duty

Lubrication remains one of the most critical factors influencing bearing performance in rough-duty environments. Given the high contamination risk, grease with extreme-pressure (EP) additives, solid lubricants, and water-resistant formulations is often preferred. Automatic lubrication systems are now common in large mining and construction equipment to ensure continuous lubricant supply, even during extended operation.

These systems reduce human error, optimize grease consumption, and ensure consistent application. In cold-climate mining regions, low-temperature greases are engineered to maintain flow and film strength, while high-temperature-resistant lubricants are used near engines and hydraulic systems.

Shock Load and Vibration Management

Mining and construction machinery frequently faces unpredictable, high-impact loads—whether caused by rock fragments, sudden bucket impacts, or explosive forces. Bearings must therefore be designed with high roller and ring stiffness, pressure distribution optimization, and cage structures capable of absorbing transient shock waves. Vibrating equipment such as screens, feeders, or compactors require bearings with tight radial clearances, heat stabilization, and special cage geometries that withstand continuous oscillatory loading. Finite Element Analysis (FEA) and dynamic simulation have become standard in designing these bearings, ensuring that roller profiles and raceway shapes minimize stress concentration and delay fatigue initiation.

Reliability Engineering and Predictive Maintenance

With the rising scale of mining operations and the demand for higher productivity, the focus is shifting from just rugged design to predictive reliability. Sensor-integrated bearings and IoT-based monitoring systems are being deployed in heavy-duty equipment to track temperature spikes, vibration patterns, grease condition, and load cycles. This transition to smart bearing technology allows operators to anticipate failures before they happen, schedule maintenance proactively, and reduce catastrophic machine breakdowns. Predictive analytics is emerging as a major contributor to improved equipment utilization and safety in hazardous mining environments.

Applications Across Mining and Construction Equipment

Different machines demand distinct bearing characteristics depending on the nature of work and loading patterns. Excavators require high-load slewing bearings, bucket linkage bearings, and travel motor bearings built for impact strength. Drilling rigs rely on precision bearings for rotating heads and stabilizers. Haul trucks depend on high-capacity wheel bearings capable of supporting enormous loads during continuous duty cycles. In crushing plants, bearings face severe shock and vibration, requiring heavy-duty cylindrical or spherical bearings with high heat stabilization. Across conveyors, pumps, screens, crushers, dozers, loaders, dumpers, and drilling machinery, bearings are foundational to safe, uninterrupted operation.

Driving Efficiency, Productivity, and Safety

Higher-performing bearings directly contribute to improved fuel efficiency, better load handling, and reduced downtime on mining and construction sites. The lifecycle economics are significant; even small improvements in bearing design or lubrication can translate into years of extended service life and substantial cost savings. Safety is also enhanced when critical components operate reliably, reducing risk of sudden equipment failure that could endanger workers or disrupt operations. The ongoing shift toward electric and autonomous off-road equipment will further amplify the need for precision, ruggedized bearings designed for long duty cycles and minimal maintenance.

Built for the Toughest Work on Earth

The mining and construction industries represent the ultimate proving ground for bearing technology. From resisting abrasive contaminants to absorbing brutal shock loads, bearings in these sectors must perform consistently in conditions where engineering margins are thin and uptime is invaluable. With advancements in material science, sealing solutions, lubrication engineering, and predictive monitoring, modern bearings are delivering unprecedented reliability and performance. As global demand for minerals, infrastructure, and construction grows, the role of robust, intelligently designed bearings will continue to expand—keeping the world’s most demanding machines moving, digging, crushing, and building.