Slewing bearings, also known as slewing rings or turntable bearings, are large, heavy-duty rolling bearings designed to support axial, radial, and tilting moment loads simultaneously while enabling rotational or oscillatory motion. These specialized bearings are central to applications where heavy loads must rotate efficiently and smoothly around a fixed axis. Their capability to combine rotation with sturdy load-bearing characteristics makes them indispensable in many industrial, construction, and transportation systems.

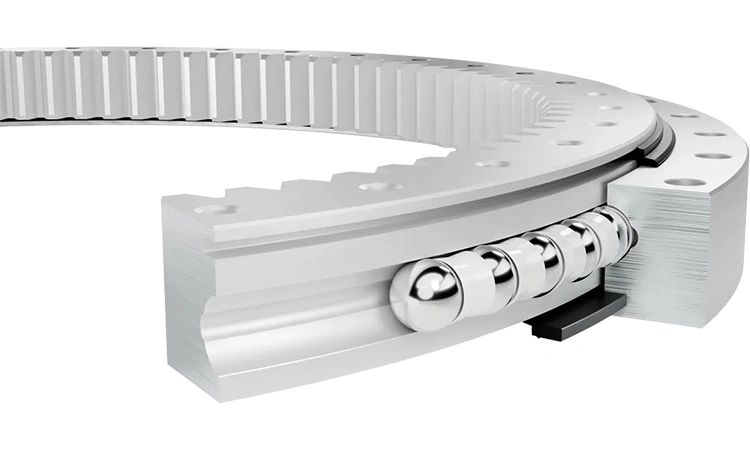

A Typical Slewing Bearing

A typical slewing bearing consists of two rings – an inner ring and an outer ring – between which rolling elements such as balls or rollers are arranged in one or multiple rows. Depending on the design, the bearing may incorporate gearing on the inner ring or outer ring that allows direct mechanical drive.

This eliminates the need for a separate gear mechanism, simplifying the structure and reducing space requirements. Slewing bearings are generally compact and lightweight relative to the large loads they handle, and can accommodate mounting structures using simple bolt arrangements through holes provided in the rings.

Design Features

Design features vary according to performance demands. The most common types include single-row four-point contact ball bearings, capable of withstanding axial loads in both directions and moderate radial forces; double-row ball bearings, offering higher load-carrying capacity and better moment resistance; and crossed roller bearings, designed for high precision and rigidity in applications requiring smooth rotation and minimal deflection. For extremely heavy or shock loads, three-row roller slewing bearings are used, with independent load paths for axial and radial loads to ensure maximum stability and durability.

Sealing is an essential design element in slewing bearings, as it prevents contaminants like dust, moisture, and metal particles from entering and damaging rolling surfaces. Grease lubrication is commonly employed, with provisions for periodic relubrication through lubrication holes. Advanced sealing materials and lubrication channels extend service life and ensure consistent performance, especially in harsh environments.

Applications

Slewing bearings are widely used in construction and material handling equipment such as cranes, excavators, aerial work platforms, and concrete pumps, where continuous rotation and load-bearing are critical. In these systems, the bearing forms the rotational interface between the upper structure and the undercarriage, enabling precise movement and stability even under dynamic loads.

In renewable energy, wind turbine yaw and pitch systems rely heavily on slewing bearings to adjust the nacelle direction and blade angle for optimal power generation. The bearings must withstand not only the considerable structural loads but also continuous exposure to weather and fluctuating stresses.

Industrial turntables, robotics, medical equipment such as CT scanners, mining machinery, harbor cranes, and offshore platforms are additional sectors where slewing bearings are essential. Their ability to accommodate compact installation, high load tolerance, and rotational flexibility enables engineers to design equipment with improved motion control, greater safety, and enhanced productivity.

Overall, slewing bearings are a cornerstone of modern rotating equipment engineering. Their versatility, structural strength, and optimized load-carrying design allow critical systems across industries to operate reliably and efficiently, making them indispensable in both stationary and mobile heavy-duty applications.